|

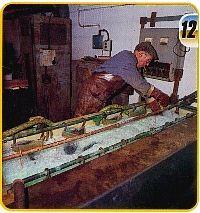

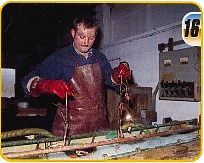

Now comes the fun part. With all the lengthy preparation work done correctly, the actual plating process seems quite simple. Steel parts go straight into the fizzy green nickel tank first. Here, Mick is adding the headlight rims into the tank at the same time as the bumper. It Is very important that no parts touch while in the tank or the finish on them both will be spoilt. |  |

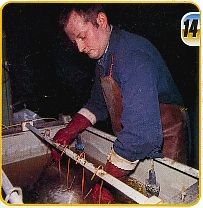

Cast zinc handles dissolve In the acid- plating solutions. To prove this, you can see them fizzing away while they are rinsed through the sour rinse tank. |

|

From here, they go into a particularly lethal combination of cyanide and copper. This layer is to protect against the acid in the plating solutions. |  |

Next it's into the acid copper tank, to add a further layer of copper before chroming. These extra stages aren't necessary with good quality steel, but are vital due to the composition of the zinc alloy. |

|

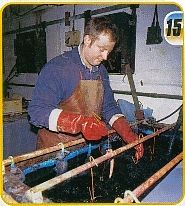

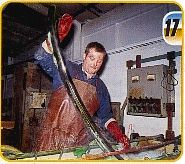

All the zinc- based parts then have to be mopped again to provide the polished base for the chrom Here, Alan is towering the polished and wired parts into the nickel tank. |  |

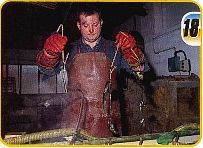

After about one hour, Alan removed our bumper from the nickel tank for inspection. |

|

Provided the finish is up to standard (and it most definitely was) the items go from the nickel tank, then through the counterftow rinse system and ... |  |

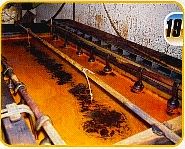

... into this, devilish- looking concoction, which is the actual chroming tank itself. |  |

| |