|

|  |

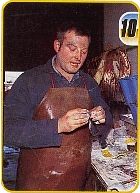

After

polishing,

each item has

to be cleaned

with vienna

lime, to

remove any

traces of

polishing

compound,

and then

individuatty

copper wired

again for

cleaning and

to go into the

plating tanks. |

|

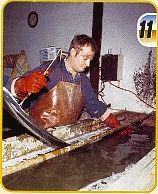

The cleaning process starts by hand

brushing in an industrial cleaning fluid,

followed by a dip in an electrically-

charged cleaning tank (see picture). This

removes all oxides from the surfaces plus

the instant tarnish that occurs as soon as

bare metal is exposed to the atmosphere.

Next, the parts are run through Marque

Restore's 'counterflow rinse system', or

cleaned in their series of progressively

cleaner fresh water swill tanks, to give it

the less technical term. Finally, they go

through a 'sour rinse'- a io% acid

solution which neutralises any sticky

deposits left over from the cleaning

processes. Although this sounds like it

takes a long time, speed is of the essence

at this stage of the process, and

unfortunately Atan wasn't able to hang

around between tanks while we set up

arty shots for the mag - sorry!

|